THE NEXT STEP

TO THE FUTURE

IN COIL FEED LINES

THE NEXT STEP

TO THE FUTURE

IN COIL FEED LINES

PLAY

THE NEXT STEP

TO THE FUTURE

IN COIL FEED LINES

PLAY

flexibility and versatility

Italian quality

exported

all over the world

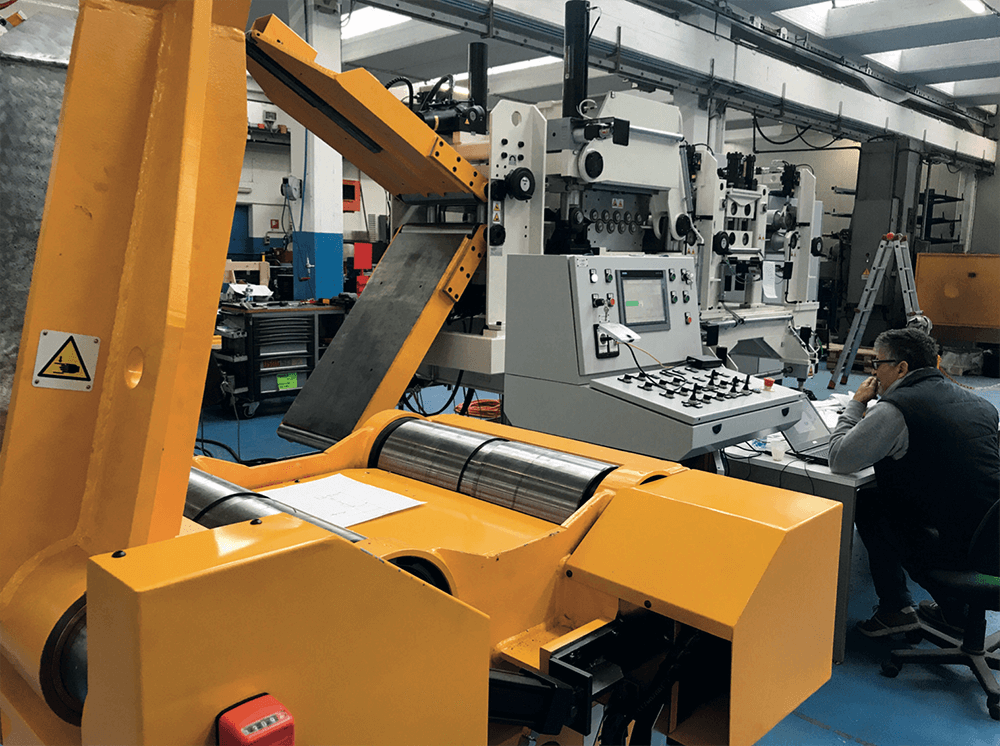

Production solely in Italy

but strongly oriented towards

export.

Possibility of controlling

the process from start to finish, guaranteeing

flexibility and quality

Some of our figures

customers throughout our history

0

custom made for customers

0

lines installed all over the world

0

active customers

0

employees

0

investments in R&D

+

0

%

design

avant-guard

Mechanical and software design

are produced entirely within the firm

10000 MQ

completely dedicated to line assembly and testing

Staff

highly-skilled technical and commercial staff

Ability to assemble

and test from 10 to 20 lines at the same time

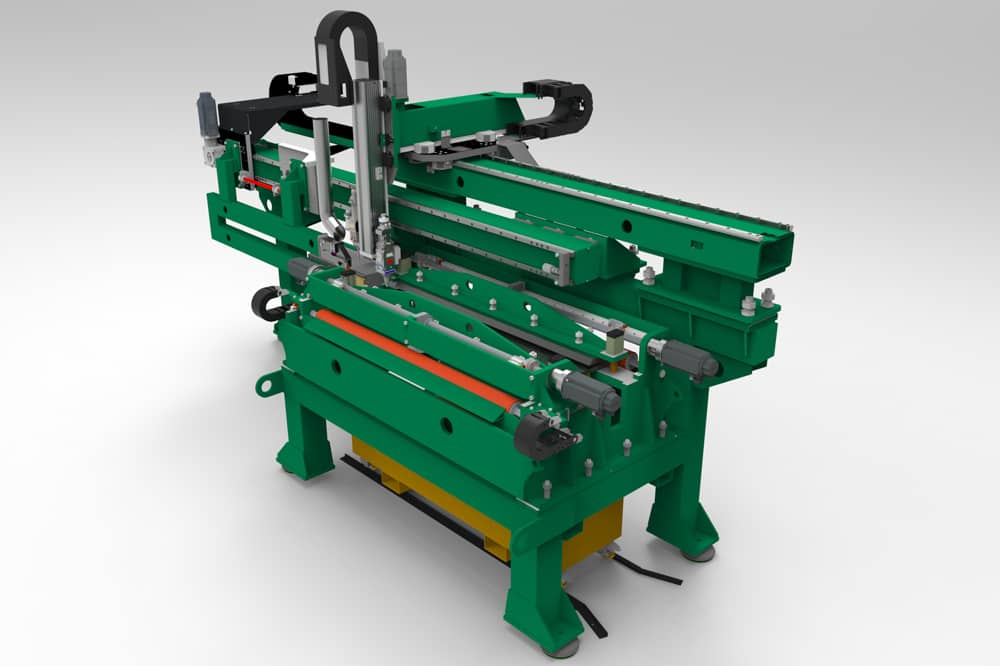

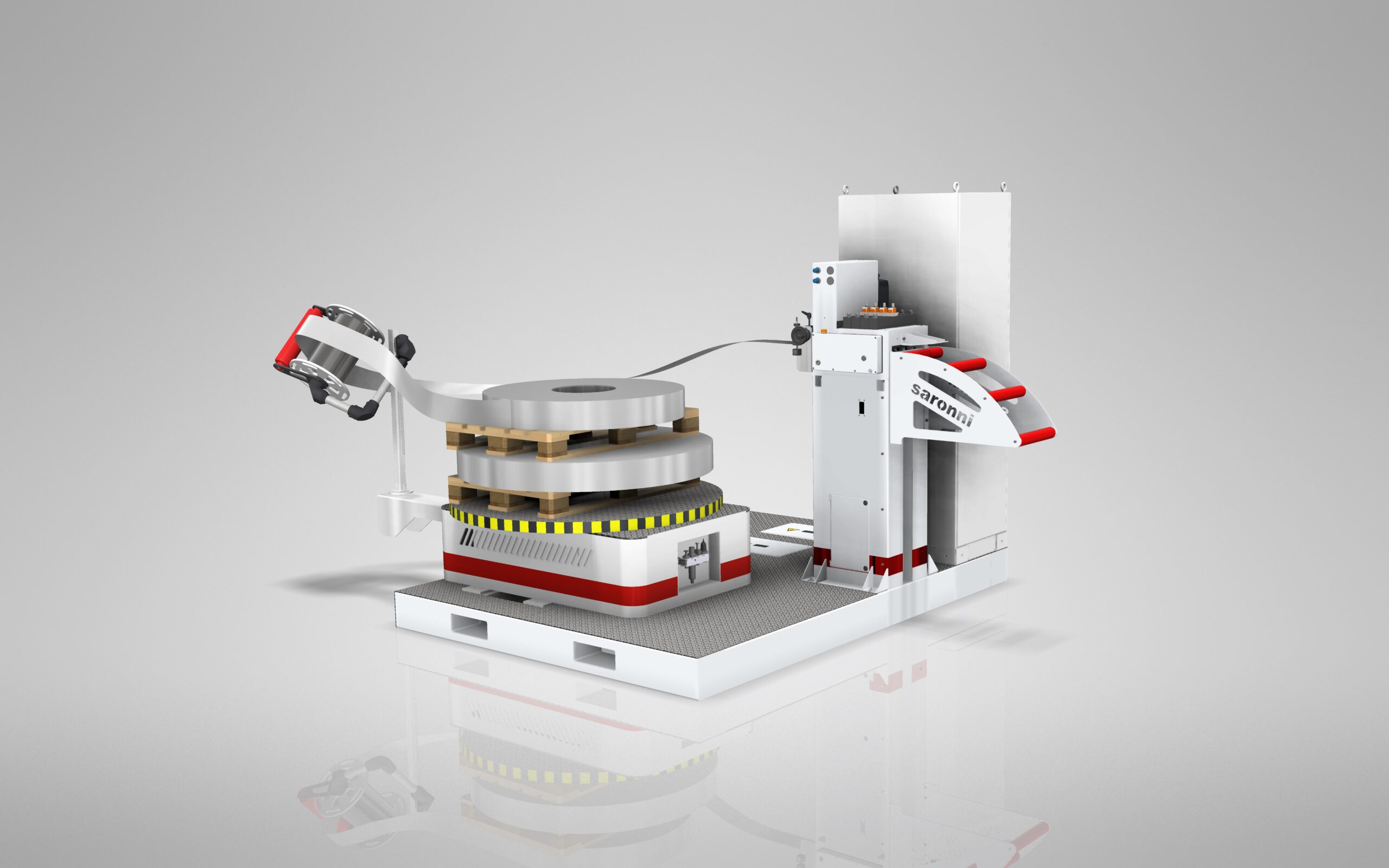

WIDE RANGE

OF SOLUTIONS

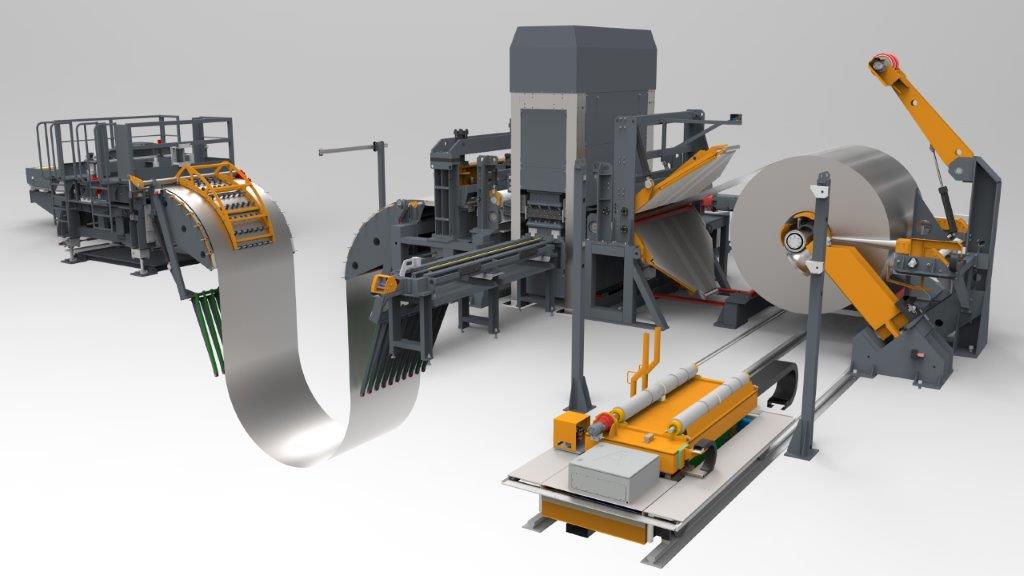

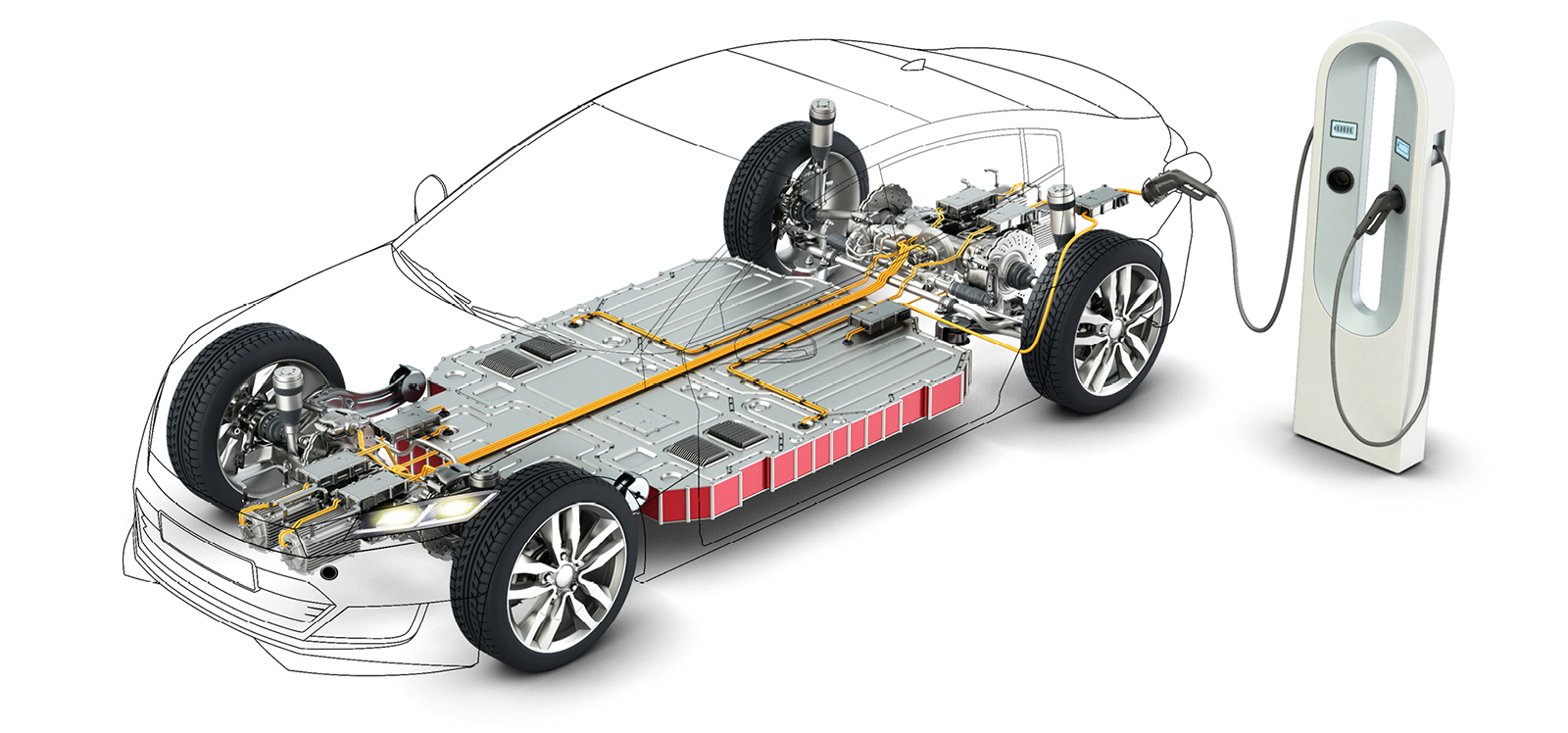

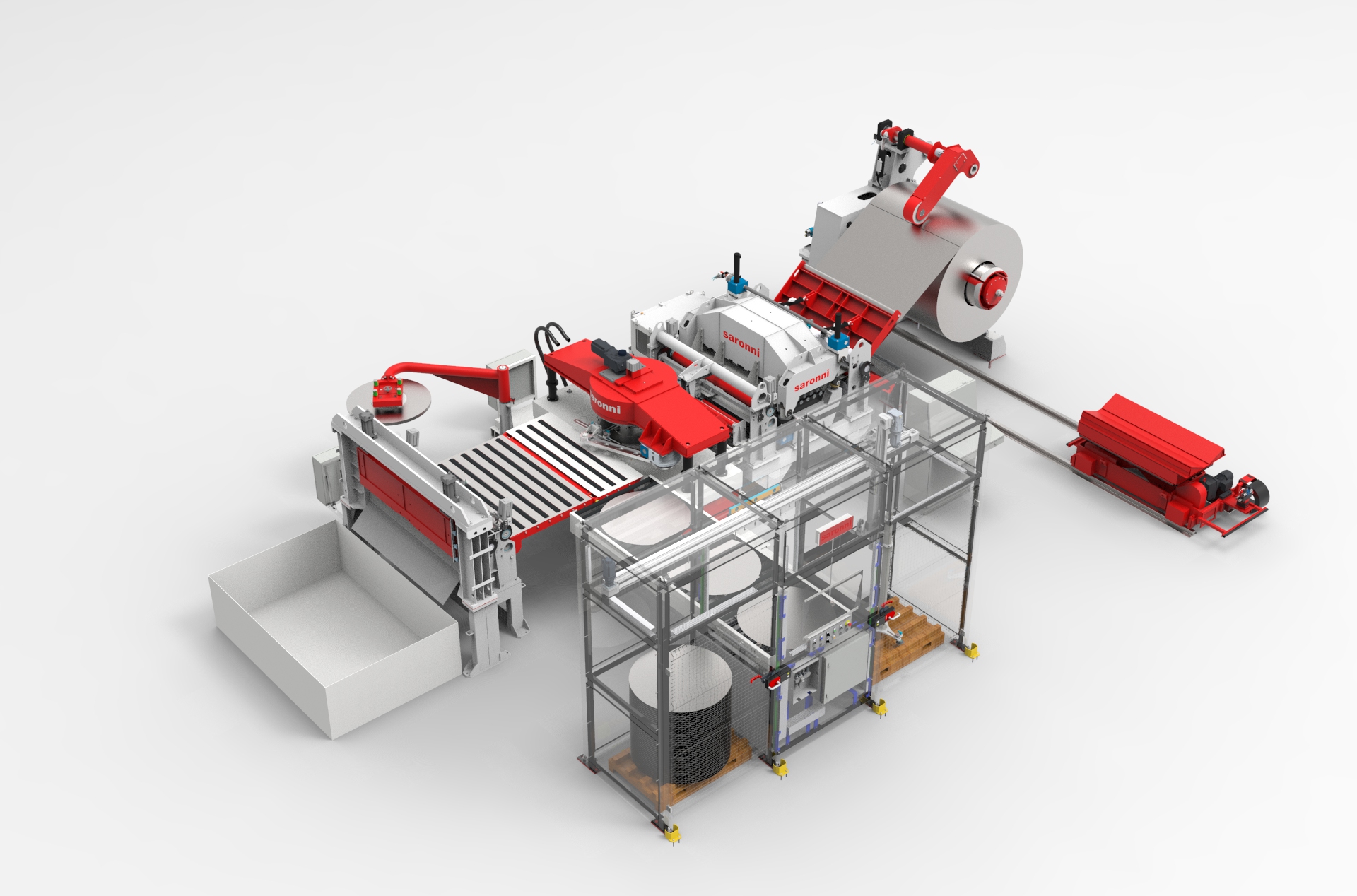

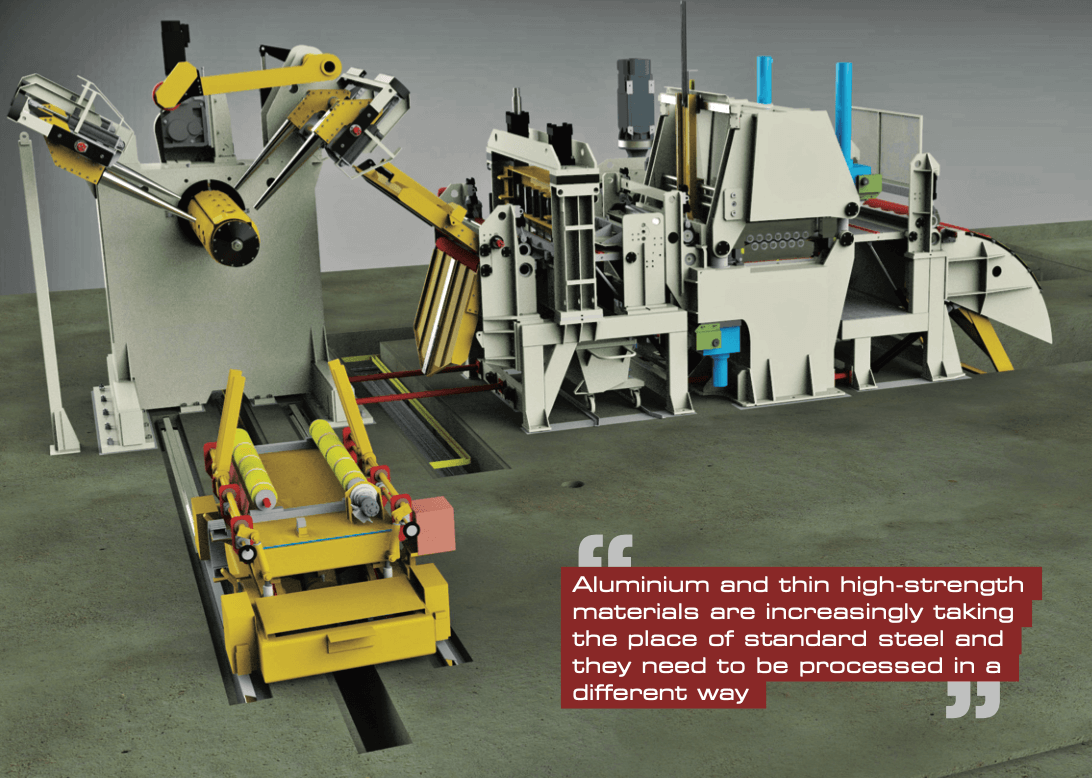

Saronni offers its customers a wide range of machines useful for solving all manner of problems in the feeding line field.

wide range

of solutions

Saronni offers its customers a wide range

of machines useful for solving all manner of problems

in the feeding line field.

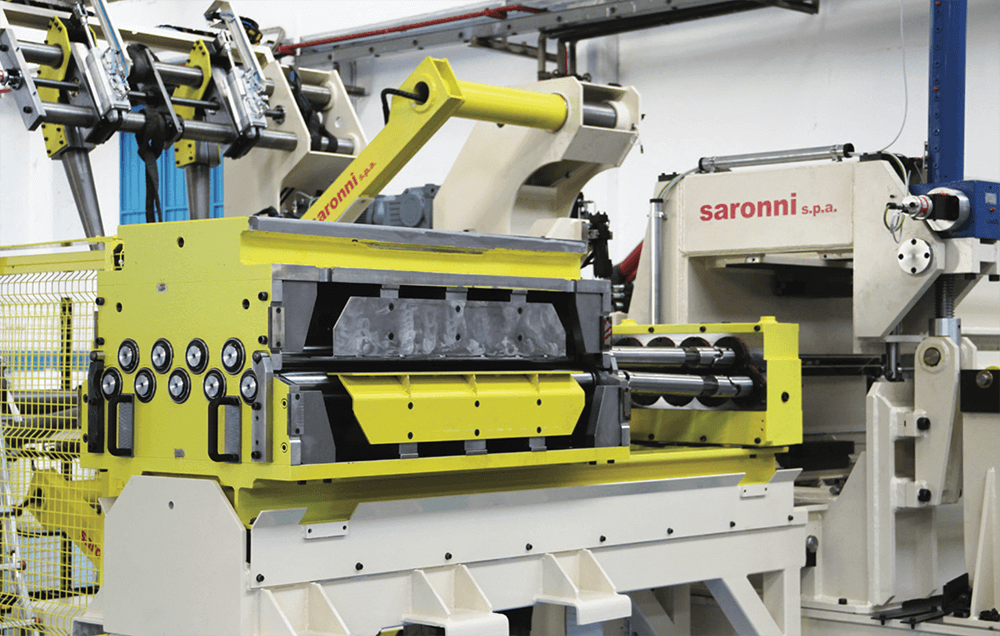

Straightening

rolls pack

change

Levelers

ASA

Aluminium

Laser

Welding

TIG

Welding

Narrow

strips

Horizontal

decoilers

Cambio

pacco rulli

Levelers

ASA

Alluminio

Saldatura

Laser

Saldatura

TIG

Piattina

Aspi

orizzontali

case

history

DISCOVER SOME

OUR RECENT

REALIZATIONS

latest news

SCROLL NEWS >

-

Via Castelletto Ticino 105

28040 Borgo Ticino (NO) ITALIA - T +39.0321.90164

- info@saronni.it