SINCE 1950 THE CORPORATE GOAL HAS BEEN

INNOVATION

Based on great design capability

and ability to respond to the increasing

needs of customers and markets.

world

SARONNI WORLD

MORE THAN 70 YEARS OF EXPERIENCE

SARONNI WORLD

MORE THAN 70 YEARS OF INNOVATION

SARONNI WORLD

MORE THAN 70 YEARS OF CONTINUOUS GROWTH AND SUCCESS

- hundreds of active customers

- exports to 20 countries

- 5% invested in research and innovation

R&D

RESEARCH AND DEVELOPMENT A WHOLLY DEDICATED TEAM

CAREFUL OBSERVERS, FLEXIBLE MANUFACTURERS

WE ARE IN THE MARKET TO SERVE THE MARKET

PARTNERSHIP WITH TRUST

timeline

OUR HISTORY

1950

The Saronni brothers found

the Saronni company

1963

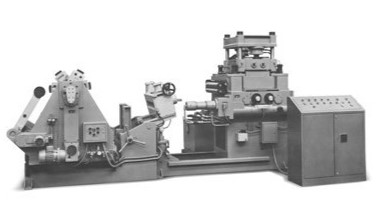

Realizzazione prima linea

alimentazione compatta

(senza ansa).

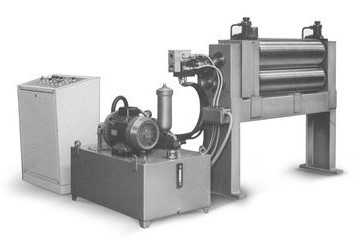

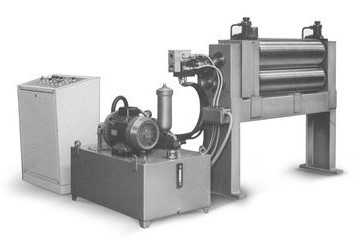

1978

Prototype of

power supply

electronic

with engine

electro-hydraulic.

1986

First line of

feeding

with regulation

automatic

managed

by PLC

1994

Commercial launch

of head/tail jumper

ribbon for crafting

front/back

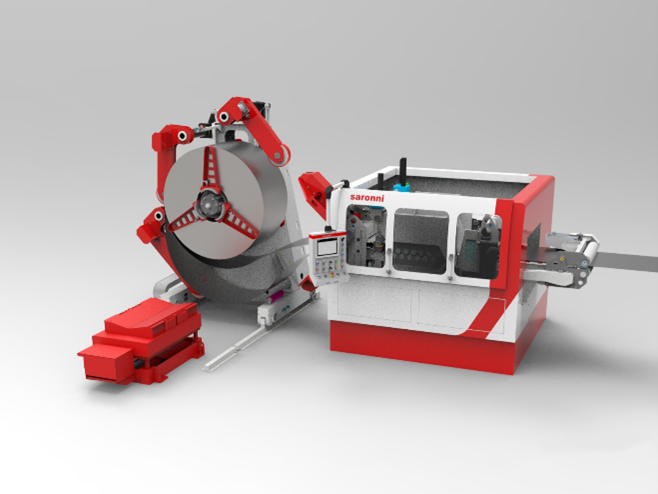

1996

Construction first

SUPERCOIL

in response

to needs

of coil change

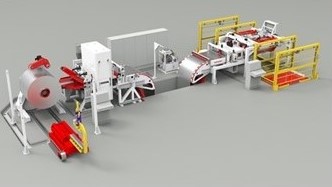

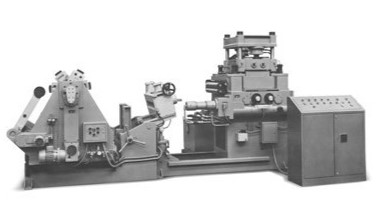

2002

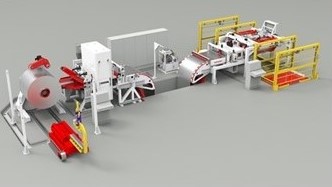

First system with

coil loading and

tape feed

fully

automatic

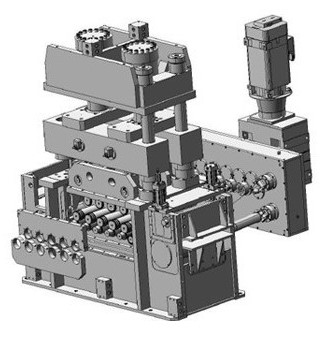

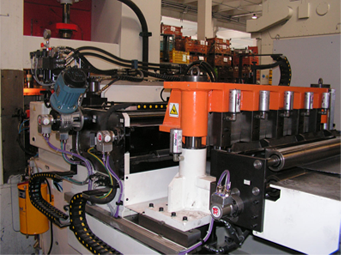

2007

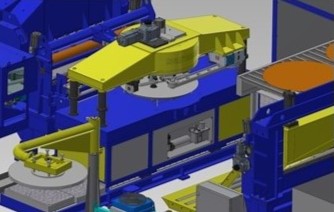

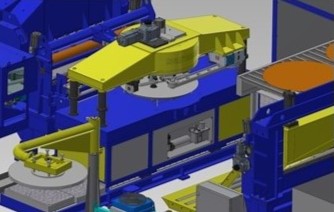

System design

flexible able

to feed both moulds

transfer and moulds

step by step

programmable

from control panel

2010

New interactive software

for automatic adjustment

straightening parameters

2011

SYNCRONAMIX:

new software for the

management of the loop in

function of the material

and the feeding speed

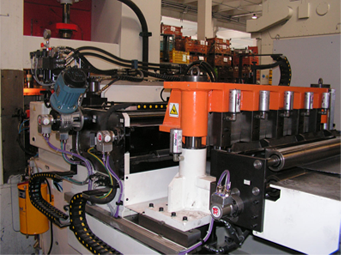

2012

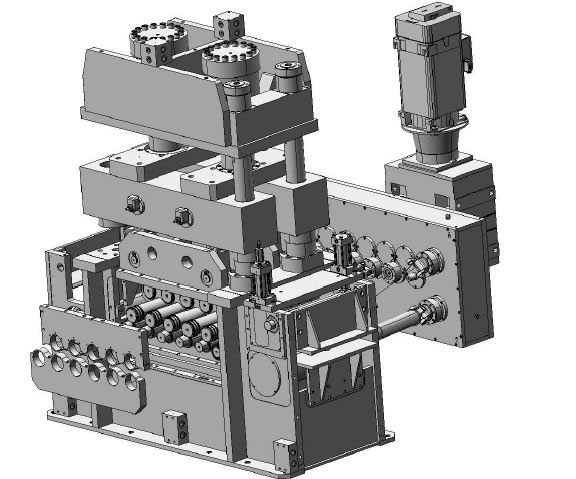

New series of

straighteners for

high strength material.

2013

First line of

feed

fully

automatic for

tape width

2,150mm.

2015

Expansion

of the range with

type

R70 straighteners for strips

up to 18mm thick.

2017

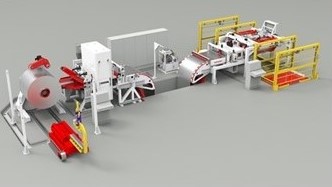

"Turnkey" supply of

combined line for

feeding

both from coils and formats.

2019

The already famous high-precision

straightening machines

dedicated to magnetic

metal are renewed

both in terms of completeness and aesthetics

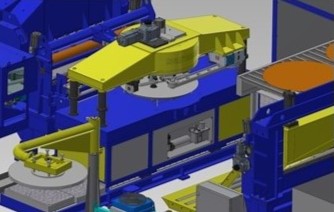

2020

Further supply of automatic

cutting and

stacking cell in

special

aluminum alloys dedicated to the

production of components for

"full electric" cars

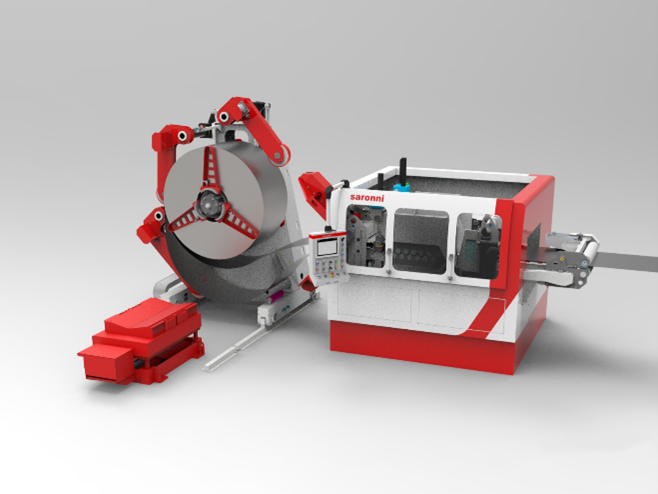

2021

The production of

disc cutters begins on

technology acquired from "Elma" to

completion of the

automatic lines

for cutting discs

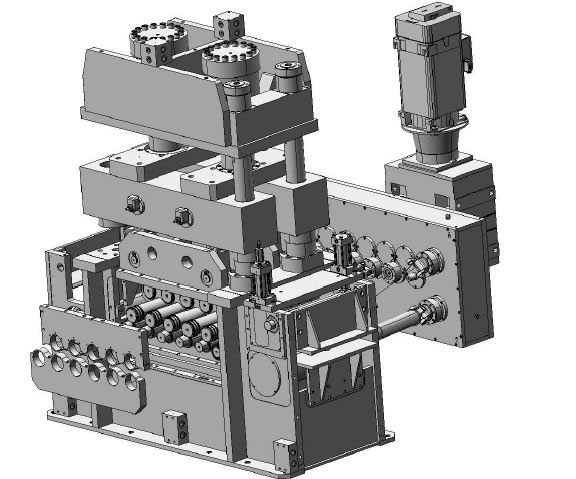

2023

Plug and play and reduction

of the overall dimensions on the ground

are some of the goals

achieved in 2023.

THE NEXT STEP

TO THE FUTURE

The Saronni brothers found the Saronni company

First feeding line with automatic regulation controlled by a PLC.

1986First compact feeding line (without loop).

Prototype of electronic feeder with electro-hydraulic motor.

First SUPERCOIL for continuous feeding.

1996

Development of a flexible system able to feed progressive and transfer dies with options programmed via a control panel.

2007Commercial launch of welded coil ends for continuous processing.

First line with completely automatic coil loading and strip head introduction.

SYNCRONAMICS: new software for loop control relative to the material type and the feeding speed.

2011

First completely automatic feeding line for strips 2.150mm wide.

2013New interactive software for automatic adjustment of the straightening parameters.

New straightener range for high-strength material.

“Turnkey” supply of a combined line for feeding from both coil and blanks.

2017

Further supply of automatic cutting and stacking cell for special aluminum alloys blanks dedicated to the production of components for "full electric" cars

2020Range extension with the new R70 type straightener for strips up to 18mm thickness.

The already famous high precision straighteners, dedicated to the magnetic strip, are renewed both for completeness and aesthetics

Plug and play and reduction of the overall dimensions on the ground are some of the goals achieved in 2023.

2023Start of the production of disc-cutting machines on “Elma” technology and know-how to complete the automatic lines for disc cutting

THE NEXT STEP TO THE FUTURE

The Saronni brothers found the Saronni company

First compact feeding line (without loop).

Prototype of electronic feeder with electro-hydraulic motor.

First feeding line with automatic regulation controlled by a PLC.

Commercial launch of welded coil ends for continuous processing.

First SUPERCOIL for continuous feeding.

First line with completely automatic coil loading and strip head introduction.

Development of a flexible system able to feed progressive and transfer dies with options programmed via a control panel.

New interactive software for automatic adjustment of the straightening parameters.

SYNCRONAMICS: new software for loop control relative to the material type and the feeding speed.

New straightener range for high-strength material.

First completely automatic feeding line for strips 2.150mm wide.

Range extension with the new R70 type straightener for strips up to 18mm thickness.

“Turnkey” supply of a combined line for feeding from both coil and blanks.

The already famous high precision straighteners, dedicated to the magnetic strip, are renewed both for completeness and aesthetics

Further supply of automatic cutting and stacking cell for special aluminum alloys blanks dedicated to the production of components for "full electric" cars

Start of the production of disc-cutting machines on “Elma” technology and know-how to complete the automatic lines for disc cutting

Plug and play and reduction of the overall dimensions on the ground are some of the goals achieved in 2023.

THE NEXT STEP TO THE FUTURE

-

Via Castelletto Ticino 105

28040 Borgo Ticino (NO) ITALIA - T +39.0321.90164

- info@saronni.it